Gypsum Plastering for Showrooms: Tips for a Perfect Finish

A showroom is not just a room; it is a stage. Whether it is selling luxury cars, diamond jewelry, or designer sarees, the environment must elevate the product. The walls of a showroom serve a critical background role—they must be flawless, invisible, and premium. A wavy wall or a cracked corner distracts the customer and subconsciously lowers the perceived value of the merchandise.

For Kanish Plasters franchisees, showroom projects are high-stakes, high-reward opportunities. They demand the highest level of technical skill (“Level 5 Finish”) and often have punishing deadlines (shop opening dates are fixed). This guide explores the specific challenges of commercial showroom plastering and the technical tips to deliver a finish that sparkles as much as the products on display.

1. The Lighting Challenge: Grazing Light

Showrooms use aggressive lighting. Spotlights, track lights, and wall washers are designed to make products pop, but they also act as “torture tests” for walls.

- The Problem: A light beam hitting a wall at a sharp angle (grazing) creates long shadows from even a microscopic bump (0.5mm). A wall that looks flat in daylight might look like the surface of the moon under showroom spotlights.

- The Solution: You must plaster under lights. Do not plaster in natural light. Set up temporary halogen work lights at the exact angles the final spotlights will be. This allows the mason to see the shadows while working and correct them instantly. This “Shadow Check” is mandatory for showroom work.

2. Durability: The “Trolley” Factor

Showrooms are high-traffic zones. Cleaning carts, product trolleys, and customers with bags constantly bump into walls.

- The Problem: Standard residential plaster might dent or chip under this abuse, especially at lower levels (skirting height).

- The Solution: Use “High-Density” or “Impact” Gypsum Plaster for the first 4 feet of height (dado level). This material cures much harder.

Also, install heavy-duty Metal Corner Beads on all external corners/pillars. These act as armor, protecting the sharp edge from chipping when hit by a trolley.

3. Speed: The Rent-Free Period

Showrooms are usually rented. The tenant gets a 30-day “Rent-Free Fit-out Period.” Every day beyond that costs them money.

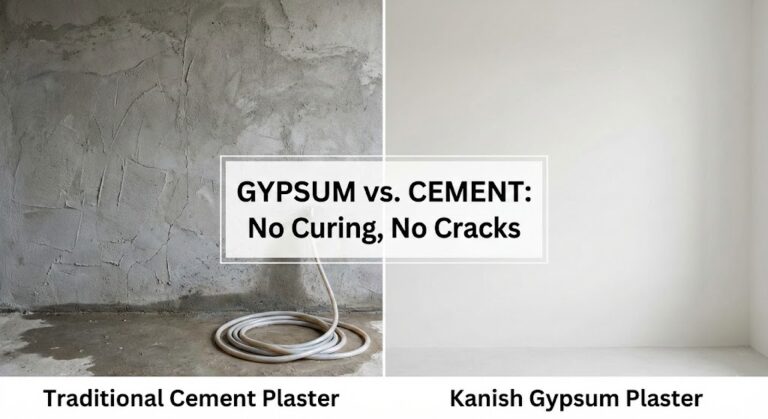

- The Strategy: This is where you pitch the speed of gypsum. “Sir, if you use cement, you wait 2 weeks for curing. If you use Kanish Gypsum, we finish in 3 days, and you can start installing your racks on Day 4.”

Deploy Spray Plaster Machines and work double shifts (night shifts are common in malls). Speed is your biggest selling point here.

4. Design Integration: Recessed Displays

Modern showrooms feature “Niches” or recessed shelves built into the wall to display hero products.

- The Application Tip: Plastering the inside of a small niche box is difficult with a trowel. Use specialized small tools (margin trowels). Ensure the internal corners of the niche are perfectly square (90 degrees). Any crookedness here will make the shelf look tilted.

Use Gypsum Bonding Agent liberally in these intricate areas to ensure the small patches of plaster stick firmly.

5. Compatibility with Cladding

Showrooms often have mixed finishes—some walls painted, some clad with glass, mirror, or wood paneling.

- The Tip: Gypsum plaster provides a perfectly plumb substrate for cladding. If you try to stick a large mirror on a wavy cement wall, the mirror will distort or crack. A gypsum wall is dead flat.

However, tell the mason not to polish the areas that will be clad. Leave the gypsum surface slightly rough (matte) to provide a “mechanical key” for the adhesive used to stick the mirror/wood.

6. The “White Box” Handover

In retail fit-outs, the “White Box” handover is a standard milestone. It means the shell is complete, white, and clean.

- The Cleanliness Protocol: Showroom floors are often expensive (Italian marble or high-end tiles) and are laid before the walls are finished in some chaotic schedules. You must use heavy-duty floor protection sheets (POP sheets or bubble guard). If gypsum droppings stain the porous marble, you will be liable for damages. Tape the protection sheets to the skirting line before starting plaster.

Frequently Asked Questions (FAQ)

Q1: Can I use gypsum in a car showroom wash bay?

No. The wash bay is a wet area. Use cement plaster and tiles. Use gypsum only for the customer lounge and sales floor.

Q2: How do I charge for showroom work?

Charge a premium (20-30% higher than residential). You are dealing with night shifts, strict security protocols, higher quality expectations (Level 5 finish), and strict penalties for delay. Do not underprice this complexity.

Q3: What if the architect wants a “Rustic” finish?

Gypsum is versatile. You can create textured finishes (swirls, concrete look) using gypsum plaster before it sets. Make a 2×2 ft sample board for approval before doing the whole wall.

Conclusion: The Silent Salesman

In a showroom, the wall should never be the center of attention. If a customer notices the wall, it’s usually because something is wrong with it. Your job as a Kanish Plasters franchisee is to create a background so perfect that it becomes invisible, allowing the product to shine. When you deliver this level of perfection, you become the preferred partner for retail chains rolling out stores across the country.